LB-Factory Supply Cheap plastic agglomerator

Plastic processed: PE/PP

Output(kg/h):50-960kg/h

Core components:Engine,Motor,PLC

Brand Name: Langbo

Screw Design:Single

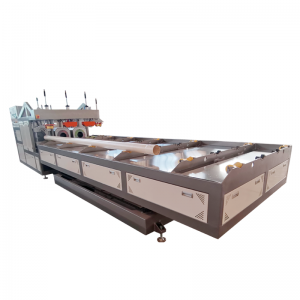

Dimension(L*W*D)10000*1200*1500MM

Applicable industries: Manufacturing

Color: Customized

After Warranty Service:Engineer to site support, spare parts, online video support.

Condition: New

Warranty of core components:1 year

Place of Origin:Zhangjiagang Jiangsu,China

Type: Recycling Granulator, PP/PE film agglomerator

Voltage:380V

Weight:3000KG

Plant Name: PP/PE film/bag agglomerator

Type: PP/PE film/bag agglomerator

|

MODEL |

LB-1600 |

LB-1000 |

LB-750 |

LB-550 |

LB-450 |

LB-300 |

LB-200 |

|

Tank volume(liter) |

1600 |

1000 |

750 |

550 |

300 |

300 |

200 |

|

Capacity(kg/hr) |

300-450 |

250-350 |

200-250 |

150-200 |

80-120 |

80-120 |

40-80 |

|

Motor power(kw) |

132 |

110 |

90 |

75 |

37 |

37 |

18.5 |

|

Discharging |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

After the waste plastic being feed into the pot of machine, the high-speed rotating blade and the fixed blade shear the materials by rotation, so that the material will soon be cut into pieces, chopped or sheet of material under centrifugal force rotation of the cutter, along the pot wall flow while under the effect of pulp material and that flip up and down movement of the center of the pot to the direction all round of the pot.

Due to the friction between itself and the friction material at high speed and the pot wall and the blade, a lot of frictional heat will be produced, the material temperature rose rapidly to reach semi-plasticized state. adhesion to each other into small pieces. Add the gauging water before the material to be agglomerated, all previously prepared material sprayed into the cold water on hot materials, evaporated quickly, heat is taken away by the material surface, so that rapid cooling to prevent caking material surface, then through rotation of the blade by blade and the fixed crushing action,plastic raw materials will be chopped a particle (size pellets of irregular heartbeat).

In the course of shredding, it may also add suitable pigment to color raw materials.

This machine can produce pellets for extrusion machines, injection machine,

With the more stringent requirements,materials can be pellets then be added into extrusion granulator and then plasticized, after granulation.

GSL series is mainly used for the production of PE, PP and other plastic film category.

GHX series of high-speed pellet machine is mainly used for pelletizing PET fibers.

The machines in LANGBO Machinery are qualified with CE and ISO certificates.