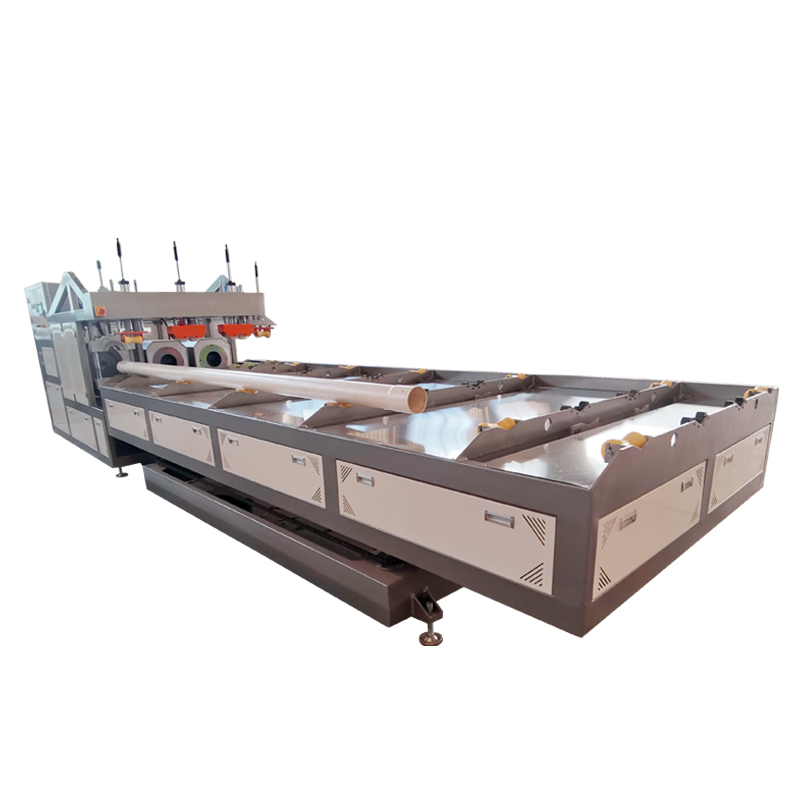

LB-The Belling Machine

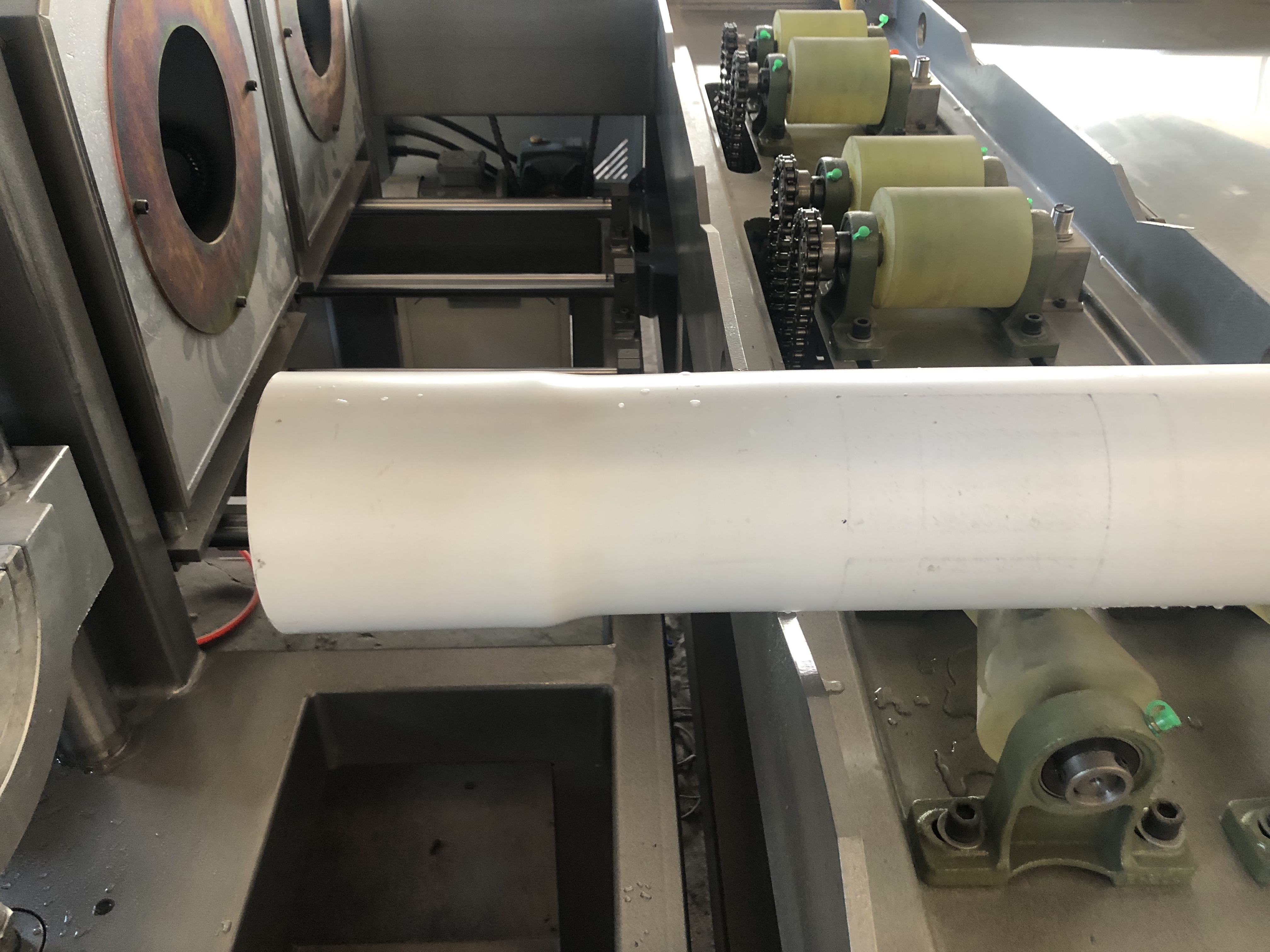

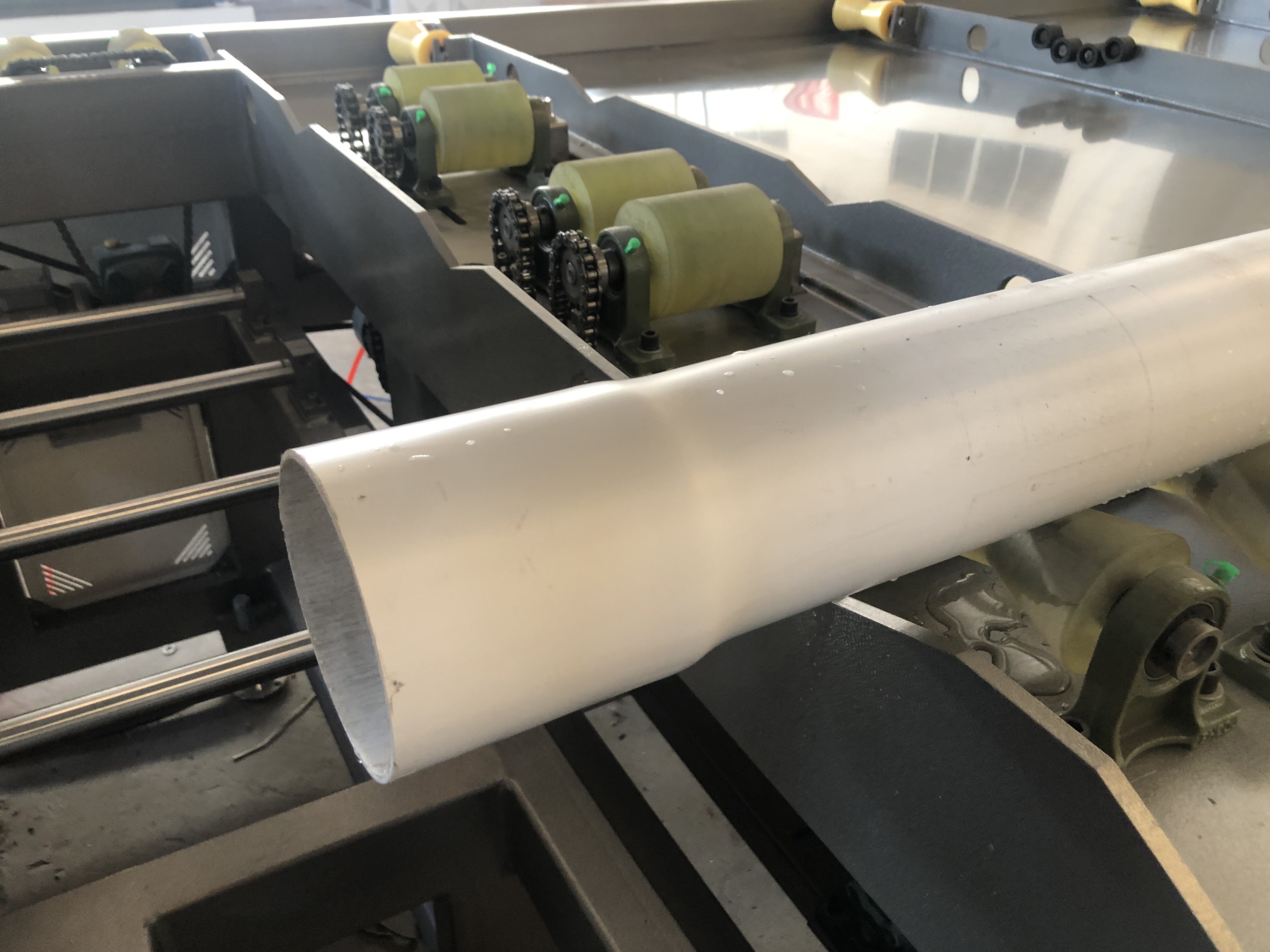

1) This belling machines can socket PP and PVC pipes in the range of 20mm up to 400mm.

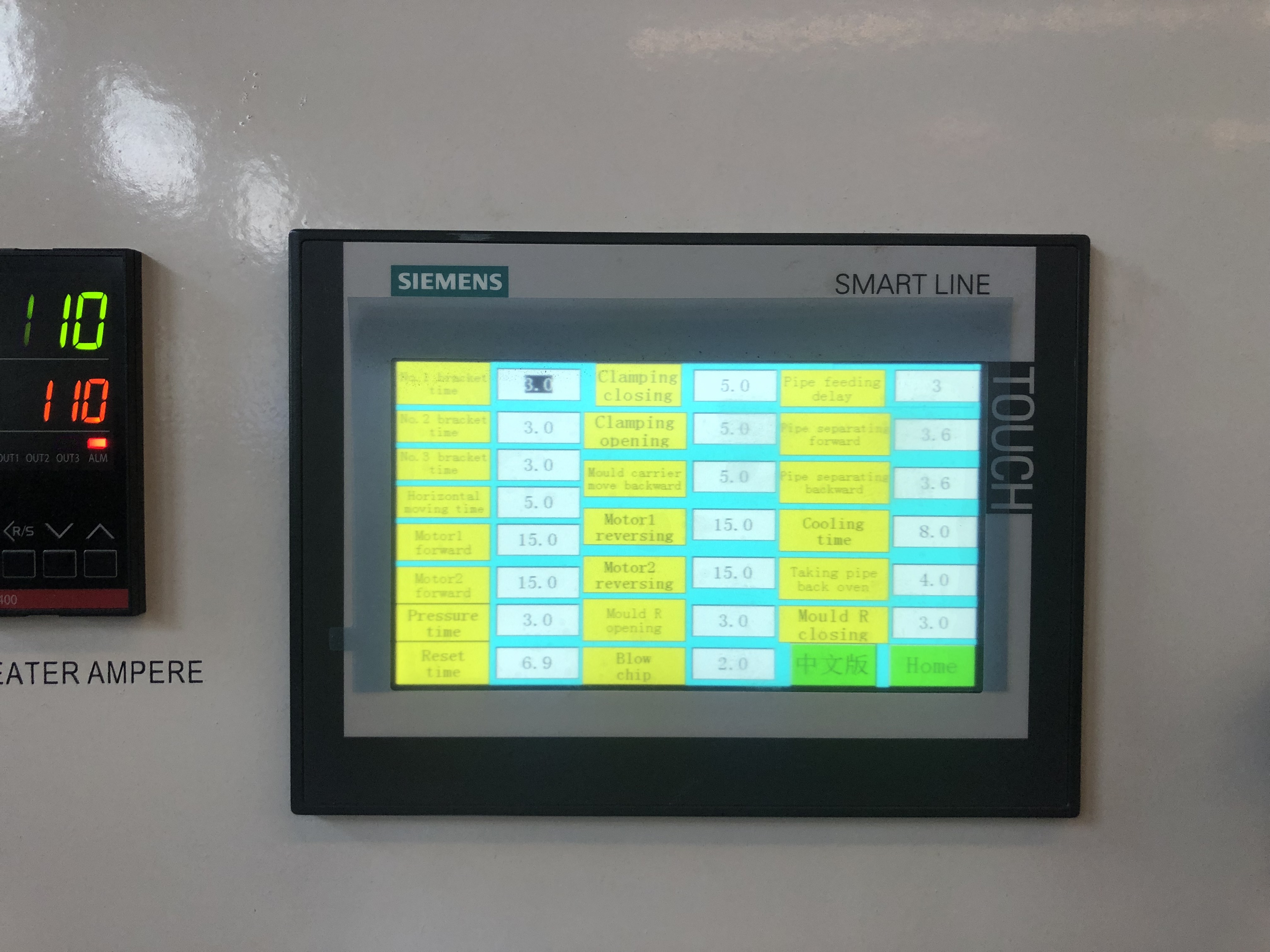

2) We offer ABB Touch screen and PLC control system which is more easy-operation.

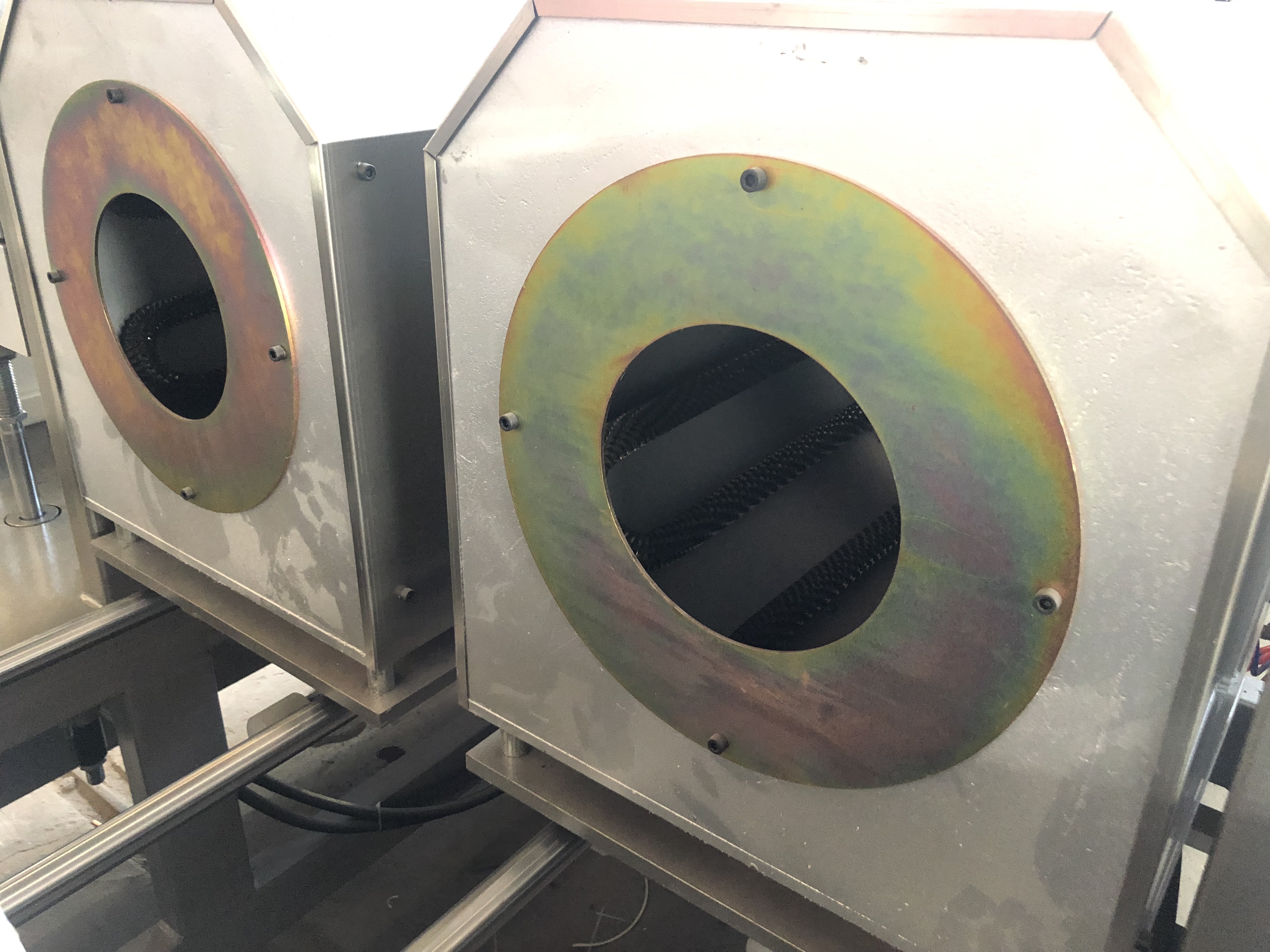

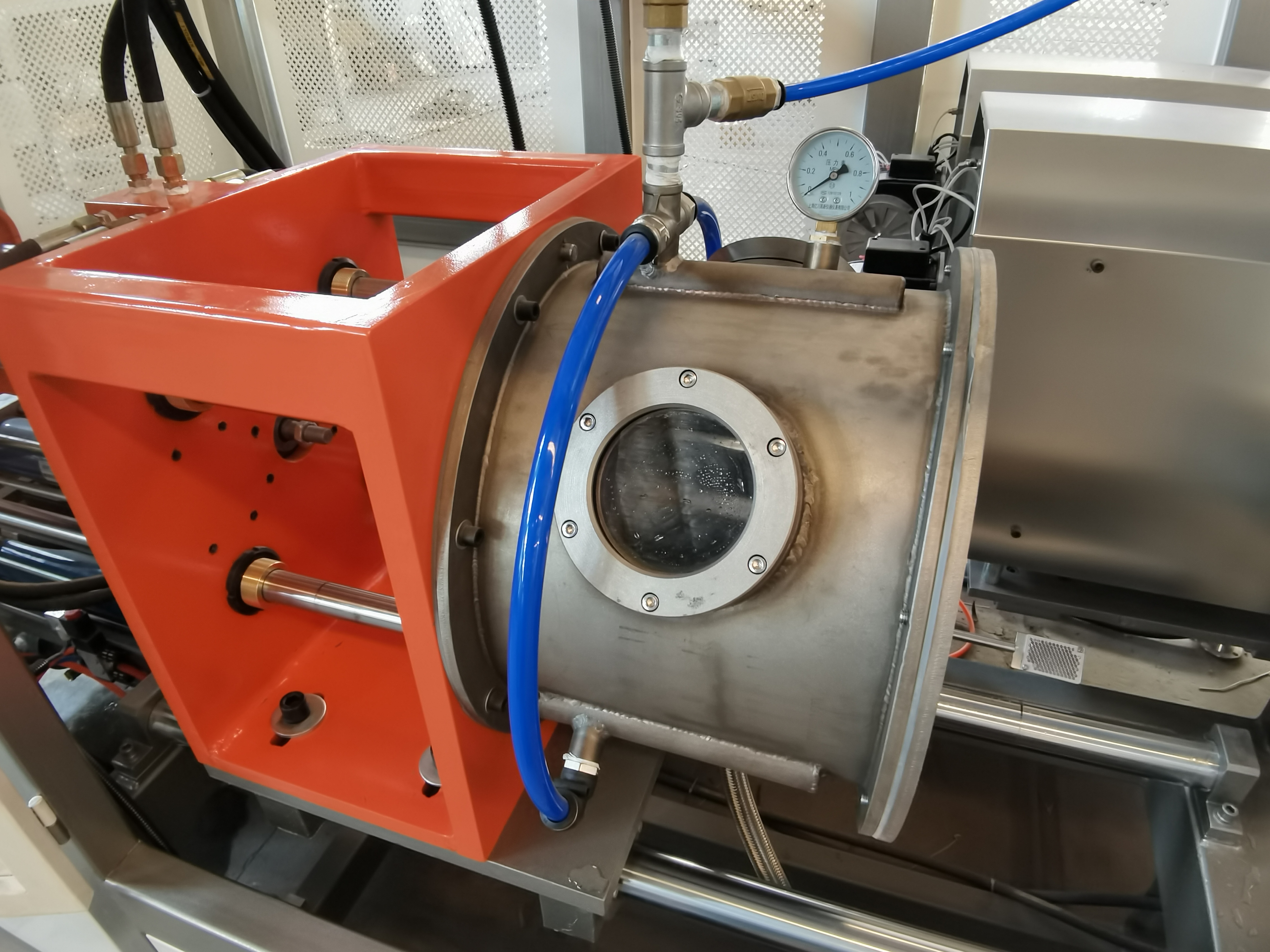

3) Special Internal heating system using inferred heaters will provide homogenous heat inside the pipe.

4) We use Hydraulic system for socketing of pipe which make the socketing process faster and much reliable and pneumatic systems are used in moving components.

5) The machine has portable holder sending the pipe to the two tanks for heating and belling.

6) It has conversion switches of expansion solvent plug (direct type) and expansion flexibility sealing washer type plug (R type) in control panel, so it is very convenient to choose the way of tube expansion, with strong craft adaptability.

|

MODEL |

Pipe diameter |

Belling way |

Cooling way |

Socket shape |

Control way |

|

SGK-40 |

16-40 (double) |

Pneumatic |

Blowing air |

“U” |

Automatic/Manual |

|

SGK-200 |

50 -200 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automatic/Manual |

|

SGK-250 |

50 -250 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automatic/Manual |

|

SGK-400 |

160-400 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automatic/Manual |

|

SGK-500 |

200-500 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automatic/Manual |

|

SGK-630 |

315-630 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automat |