-

400-710mm PVC Pipe Extrusion Line with 92/188 110KW motor

400-710mm PVC Pipe Extrusion Line with 92/188 110KW motor

The design of 400-710mm PVC Pipe:

For the large PVC pipe, it is often used in the industrial water supply pipe. It is widely used in the Saudi Arabia and middle east countries. For the large diameter pipe, its capacity can be up to 800-1000kg/h. We have much experienced in the large diameter PVC pipe. For this line, we adopt 92/188 110kw extruder to ensure the stable extrusion speed. The mould material adopts 40Cr with temperature sensor device. The motor is Siemens-beide(joint venture in China). It has 6 meters long vacuum tank and four caterpillar haul-offs.

In the extrusion process of pvc pipe, which points should be careful

During the extrusion process of CPVC (Chlorinated Polyvinyl Chloride) pipes, several points require careful attention to ensure the production of high-quality pipes. Here are some key points:

1. **Material Handling and Mixing**:

- Ensure proper handling and mixing of CPVC resin and additives to achieve uniform dispersion and consistency in the material. Proper mixing is crucial for maintaining the desired properties of the CPVC compound.

2. **Temperature Control**:

- Monitor and control the extrusion temperature carefully, as CPVC material has specific temperature requirements for processing. Maintain the temperature within the recommended range to prevent degradation of the material and ensure proper melt flow.

3. **Screw Design and Configuration**:

- Use extruder screws designed specifically for processing CPVC material. The screw design should provide adequate mixing and homogenization of the melt while minimizing shear heating to avoid material degradation.

4. **Die Design and Calibration**:

- Ensure the die design is suitable for CPVC pipe extrusion, with proper dimensions and geometry to produce pipes with consistent wall thickness and diameter. Calibrate the die properly to achieve uniform pipe dimensions.

5. **Cooling and Quenching**:

- Implement effective cooling and quenching systems to rapidly cool the extruded CPVC pipe and set its dimensions. Proper cooling is essential for preventing warping or distortion of the pipe and ensuring dimensional stability.

6. **Pulling and Sizing**:

- Control the pulling speed and sizing of the CPVC pipe to achieve the desired dimensions and surface finish. Proper pulling and sizing ensure uniformity in pipe diameter and wall thickness throughout the length of the pipe.

7. **Monitoring and Quality Control**:

- Implement a comprehensive monitoring and quality control system to detect any defects or inconsistencies in the extruded CPVC pipes. Conduct regular inspections and tests to ensure compliance with specifications and standards.

By carefully managing these points during the extrusion process, manufacturers can produce high-quality CPVC pipes that meet the required specifications and performance standards.

Extrusion line details:

Twin screw extruder machine

The extruder are crafted with top brand components to ensure production stability, efficiency and machine durability. Due to the stick feature of the PVC material, we adopt 110kw for the extrusion line to ensure the pushing force. Meanwhile our screw and barrel is specially designed to deter to the high corrosive characters.

Vacuum calibration & cooling tank

The vacuum calibration tank adopt two chamber structure: the vacuum calibration and cooling parts. Both of vacuum tank and spraying cooling tank adopt stainless 304 steel. The excellent vacuum system ensures precise sizing for pipes. We lengthen the vacuum and cooling tank to 8m. With much longer cooling process, the PVC pipe can be well cooled and have better surface.

Haul-off Unit

We adopt four caterpillar on the haul-off machine ensures produced pipe running stably and steady. The haul-off units can make tailored hauling model based on certain production requirement by adjusting the general control.

Cutting Unit

The high accuracy encoder ensures a precise and stable cutting length. With PLC control system, it can be cut by manual operation according to the specific application. Due to the high corrosive feature of the PVC material, all the surfaces of the cutting unit adopts stainless steel 304. It ensures the working lifetime of the cutting machine.

CONTACT US:

The CPVC pipe is a new and popular product among the pipes. We are much experienced in the PVC pipe production field, if you are interested, pls contact me. I can make tailed solution and send you much working videos of the PVC pipe production. Look forward to your inquiry.

-

Good Quality UPVC Silent Pipe Extrusion Line 50-160mm Hot Sales

Good Quality UPVC Silent Pipe Extrusion Line 50-160mm Hot Sales

Introduction

PVC silent pipe is one of special designed UPVC pipe. It has highly noise reduction function. The U-PVC silent pipe often starts from 50mm and its mould design differ from the normal PVC pipes. It has rotations lines inside the pipe. Therefore the mould is rotating during the pipe production. It adopts 8 meters long vacuum tank ensuring enough cooling time of U-PVC pipe. The haul-offs guarantee the pipe moving forward smoothly and stably. The gearbox and motor of our haul-offs is Redsun. Our cutter is panetary cutting system. And it has stacker to hold the finished pipe.

Extrusion line details:

Twin screw extruder machine

The extruder are crafted with top brand components to ensure production stability, efficiency and machine durability. Due to the stick feature of the CPVC material, we adopt 45kw for the extrusion line to ensure the pushing force. Meanwhile our screw and barrel is specially designed to deter to the high corrosive characters.

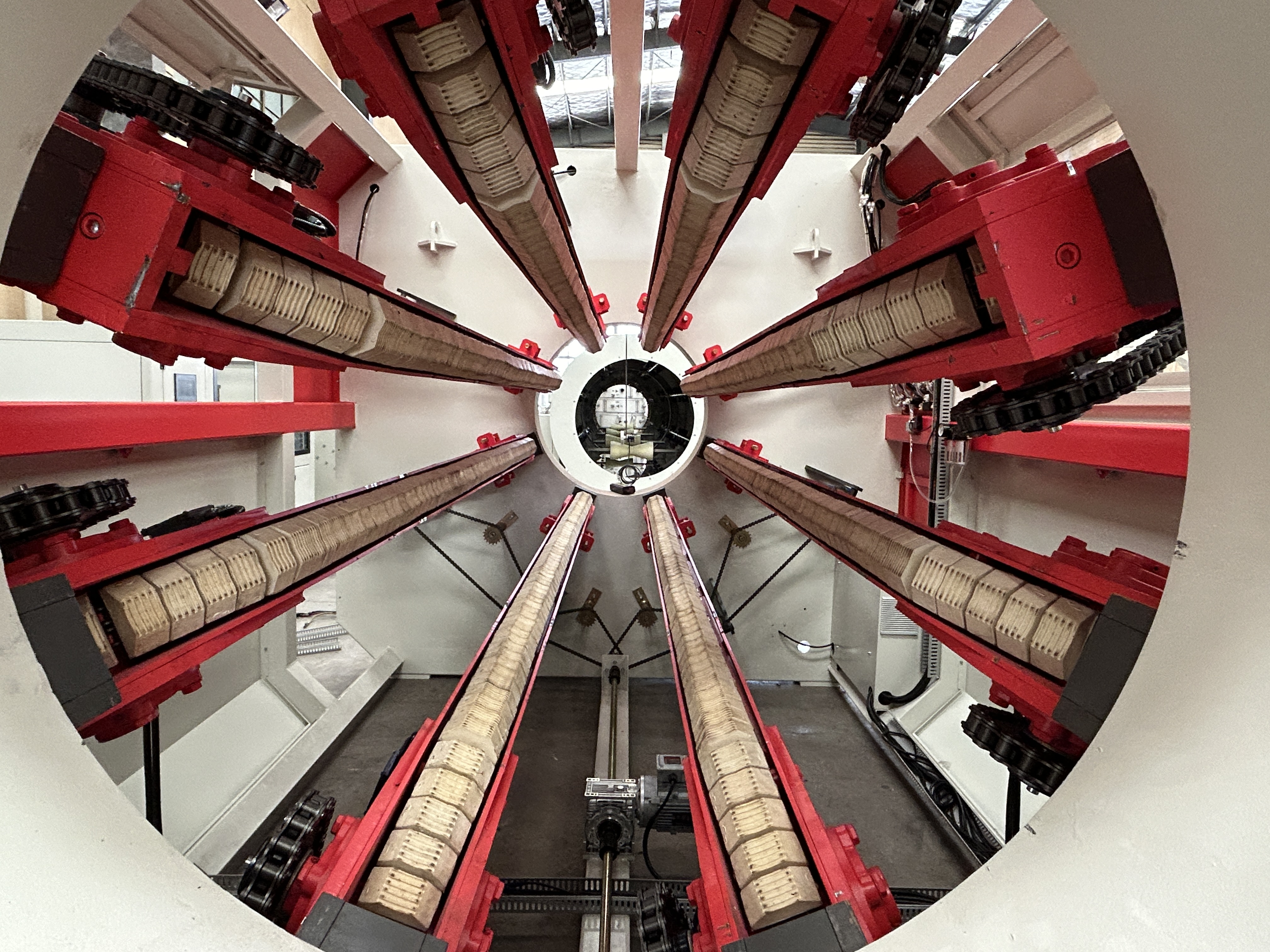

Mould

The mould design is different from the normal pvc pipe. It has spiral lines to make inner-vacuum for the silent pipe. Meanwhile the mould is rotating during production in order to make the lines for the inside of pipe.

Vacuum calibration & cooling tank

The vacuum calibration tank adopt two chamber structure: the vacuum calibration and cooling parts. Both of vacuum tank and spraying cooling tank adopt stainless 304 steel. The excellent vacuum system ensures precise sizing for pipes. We lengthen the vacuum and cooling tank to 8m. With much longer cooling process, the CPVC pipe can be well cooled and have better surface.

Haul-off Unit

We adopt three caterpillar on the haul-off machine ensures produced pipe running stably and steady. The haul-off units can make tailored hauling model based on certain production requirement by adjusting the general control.

Cutting Unit

The high accuracy encoder ensures a precise and stable cutting length. With PLC control system, it can be cut by manual operation according to the specific application. Due to the high corrosive feature of the CPVC material, all the surfaces of the cutting unit adopts stainless steel 304. It ensures the working lifetime of the cutting machine.

CONTACT US:

The UPVC silent pipe is a new and popular product among the pipes. We are much experienced in the UPVC silent pipe production field, if you are interested, pls contact me. I can make tailed solution and send you much working videos of the pipe production. Look forward to your inquiry.

-

LB-20-110mm CPVC Pipe Extrusion Line

CPVC pipe is unlike the UPVC pipe. It has highly corrosive and much sticker. It has high demand of the screw and barrel and the mould material. Meanwhile the mixed CPVC raw material is influential to the CPVC pipe making. The CPVC pipe always used as hot water supply pipe and firefighting pipe. Therefore it has thicker wall thickness.

-

LB-Conical Twin Screw Extruder

SJSZ series conical twin screw extruder is mainly composed of barrel screw, gear transmission system, quantitative feeding, vacuum exhaust, heating, cooling and electrical control components Etc. The conical twin screw extruder is suitable for producing PVC products from mixed powder due to the plastification features.

-

LB-Extruder

Langbo Machinery provides high quality plastic extruders for Single Screw and Twin Screw solutions, with a focus on the high quality and plasticizing efficiency. We customize the extruder screw design conforming to the raw material combination ensuring homogeneous mixture and better plastification.