Order Detail

Location: Tunisia

Product: Pipe Extrusion Line with Diameter Range DN20-75

With Mixer Combination and Belling Machine

Highlights

Perfect balance between wide diameter range capability and productivity

Separately control system for two strands

Energy saving by vacuum control system and permanent magnet synchronize motor

Four strand extrusion system for high efficiency

Tailored Solution

1.Mixer Combination with vacuum and spiral loading system

Based on the Requirement of PVC Processing, mixers are necessary. With Different loading concepts the process can achieve a relative low noise and mixture quality

Automatic mixing and loading

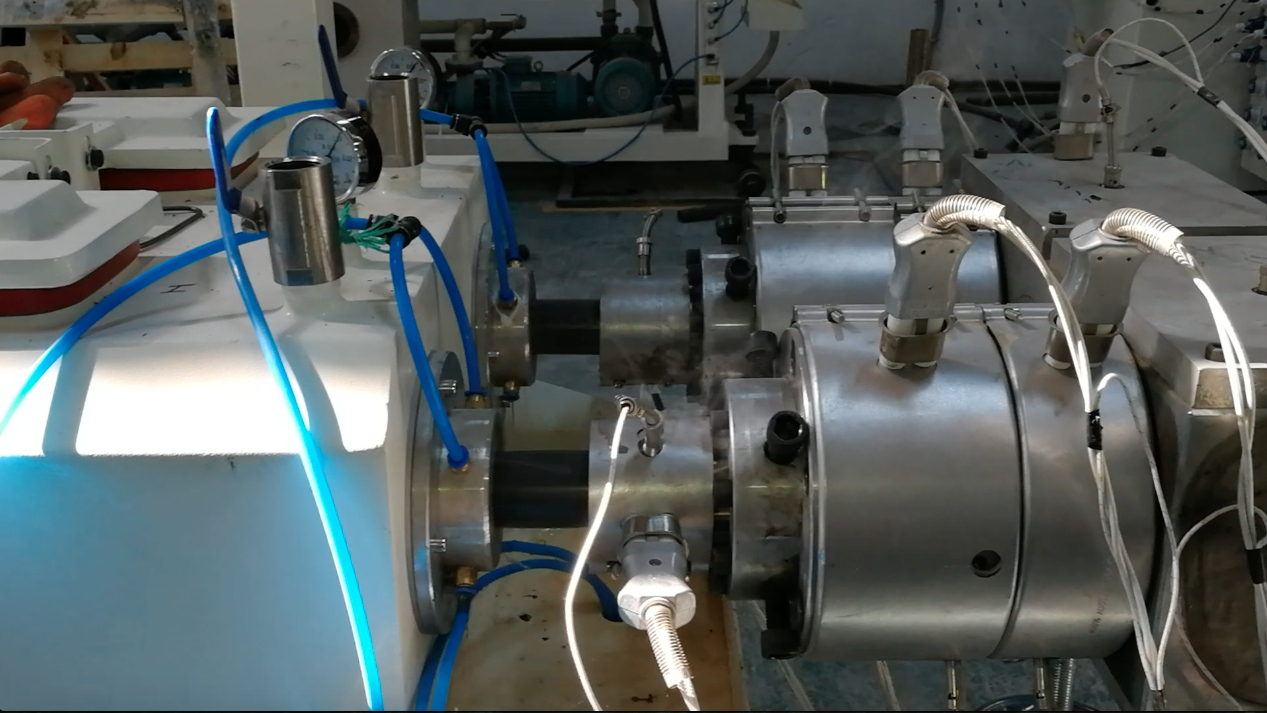

2.Double strand for wide pipe range and high productivity

After analyzing of pipe production plan and discussion with customer, we decided one double strand extrusion line for DN16-75 and one extrusion line for lager pipe production. So that the high productivity can be kept for each size of pipe production.

3.Haul-off and cutting combination

For small pipe extrusion the combination structure can save factory space.

4.Double Oven Belling machine

For belling machine, we applied two heating ovens for rapid belling process. In the belling station the pipe end is already hot and can be shaped immediately. The shaping Productivity will not be influenced by belling process.

Reference product

Mixer Combination

Double strand PVC Pipe Extrusion Line

PVC Pipe Extrusion Line

Belling Machine

Post time: Mar-23-2023