LB_75-315mm HDPE Multi layer Pipe Extrusion Machine

| MODEL | PIPE DIAMETER (MM) | EXTRUDER MODEL | MOTOR POWER |

| LB-63 | 20-63 | SJ65/33 | 55AC |

| LB-110 | 20-110 | SJ65/33 | 55AC |

| LB-160 | 75-160 | SJ75/33 | 90AC |

| LB-250 | 90-250 | SJ75/33 | 110DC |

| LB-315 | 110-315 | SJ90/33 | 160DC |

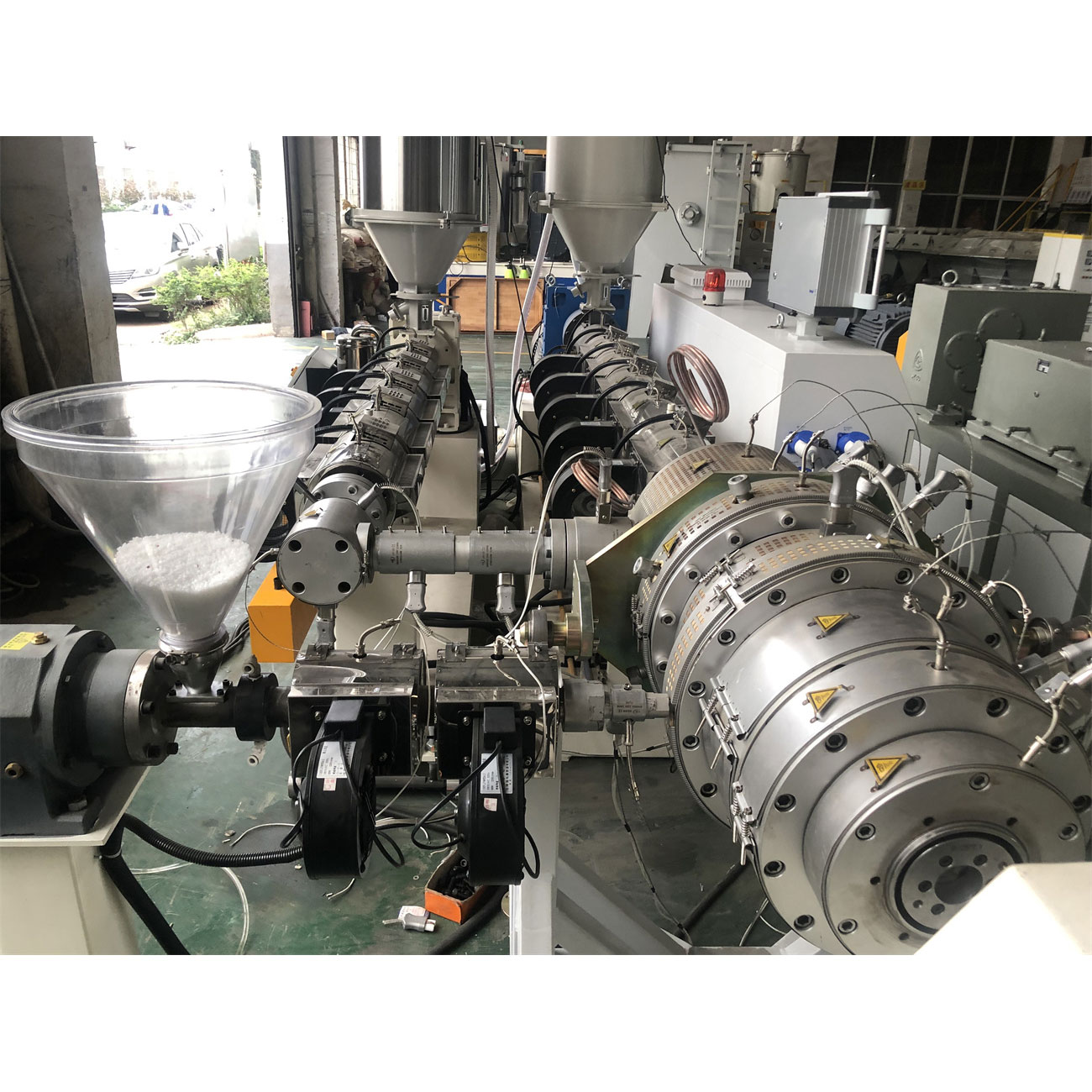

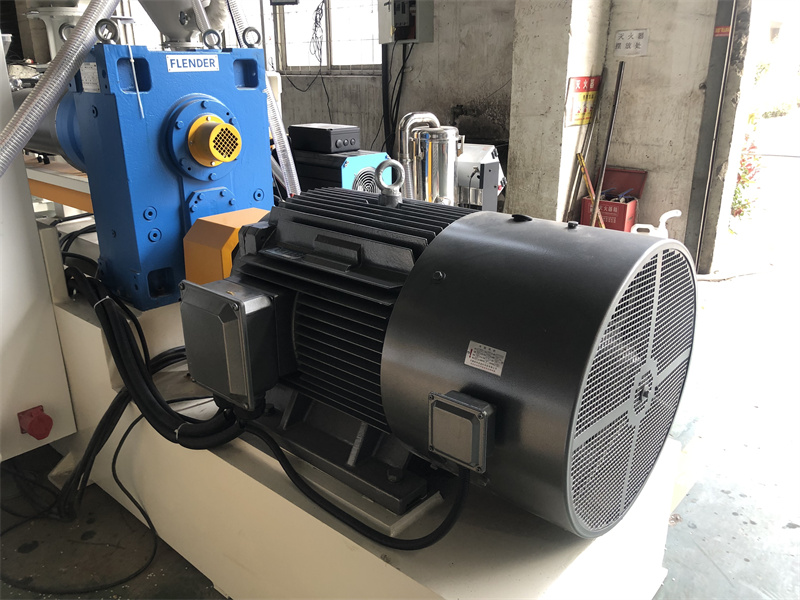

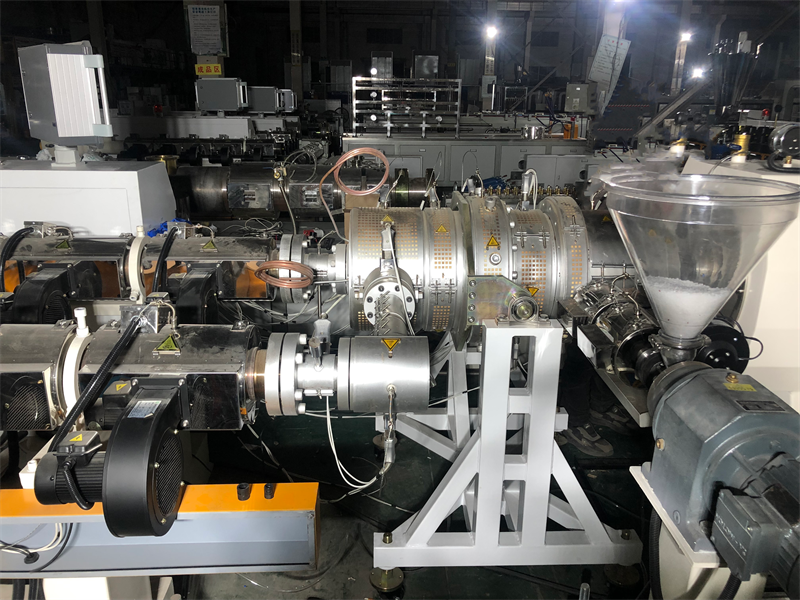

Making the multi-layer HDPE pipe, three extruders were needed. The main extruder is extruding the inner and outer layer with 160kw. Another is extruding the medium layer with 75kw. Another small extruder is line maker extruder. All the electrical elements were Schneider.

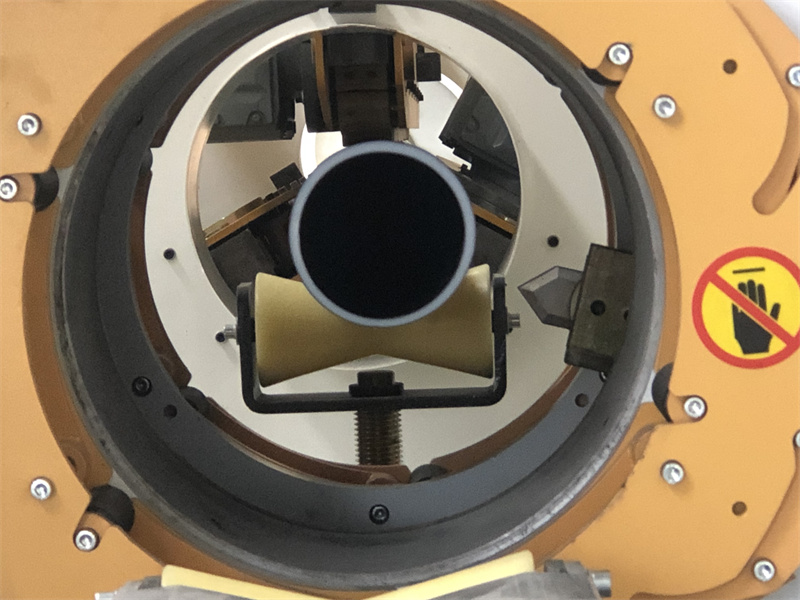

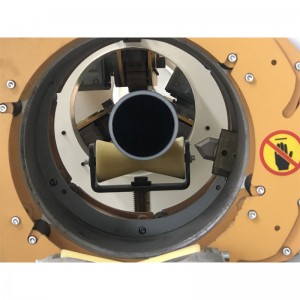

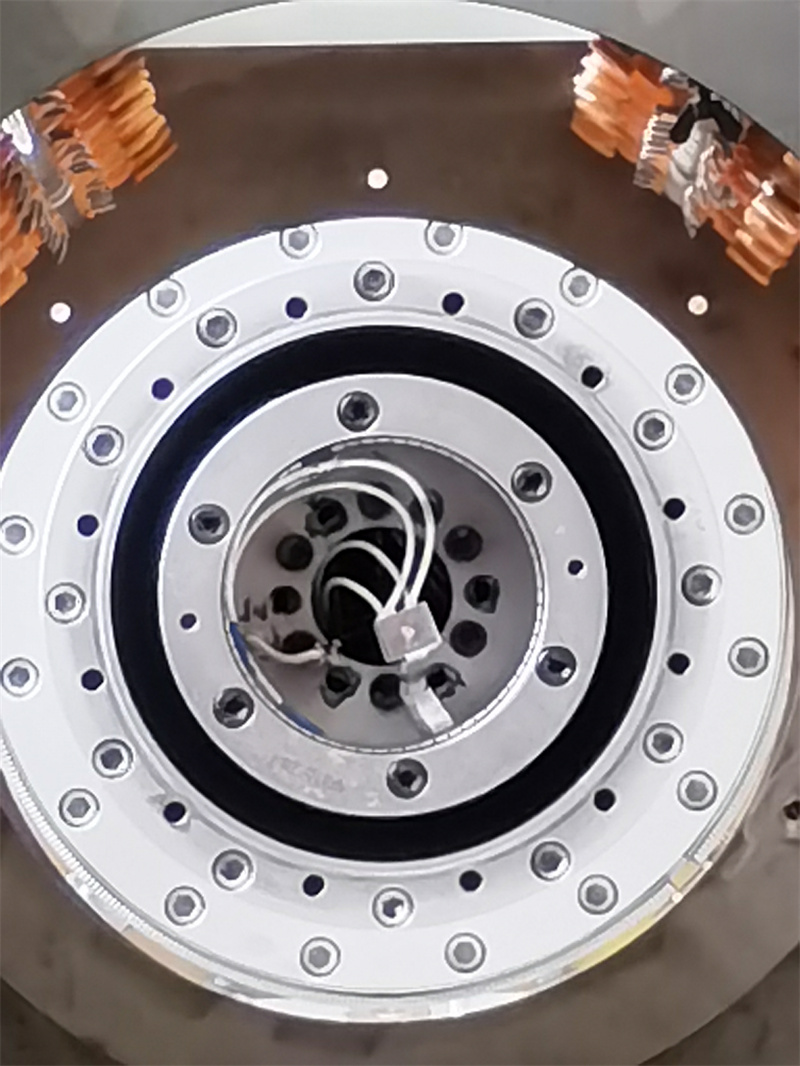

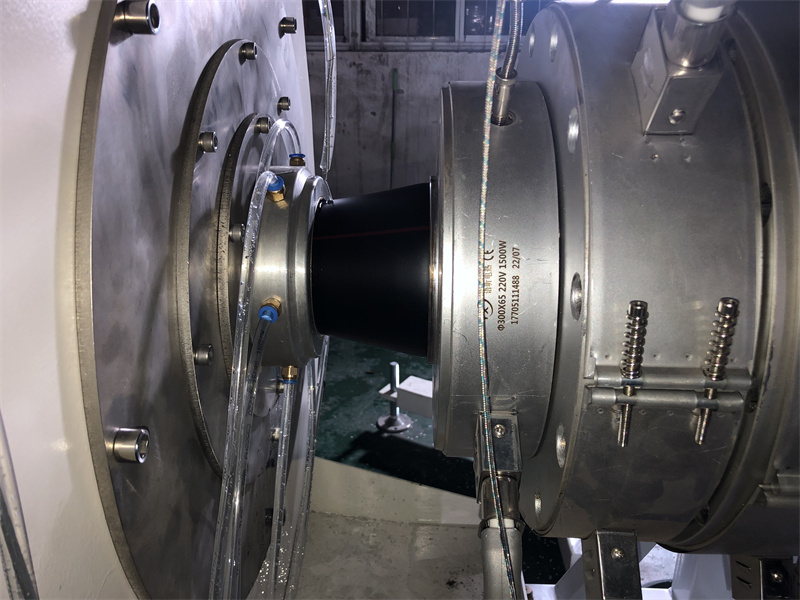

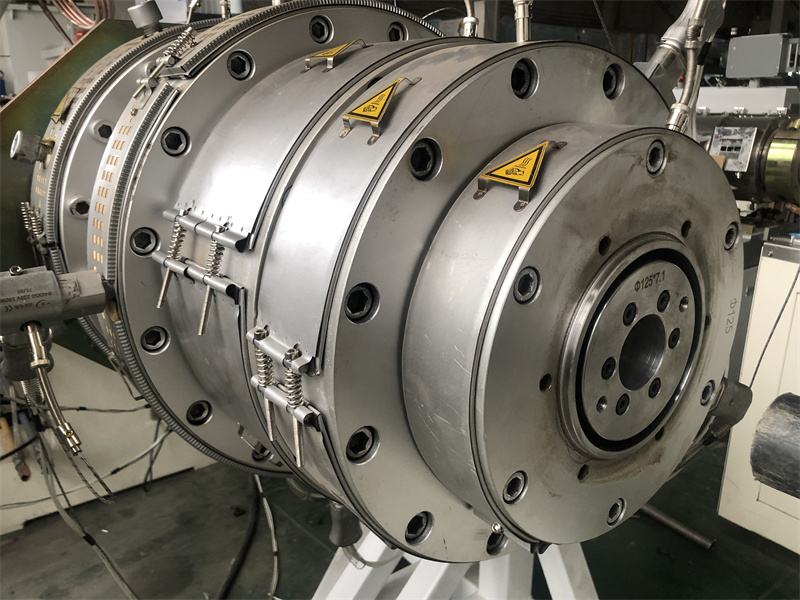

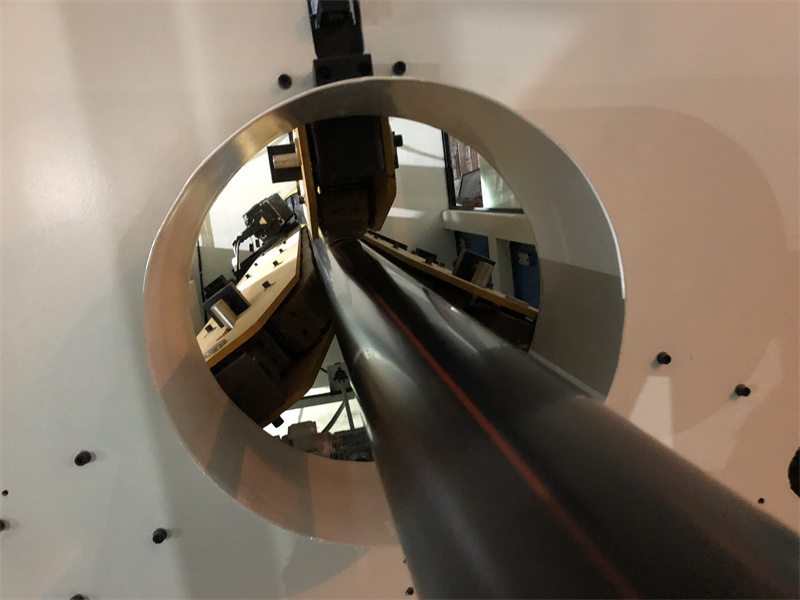

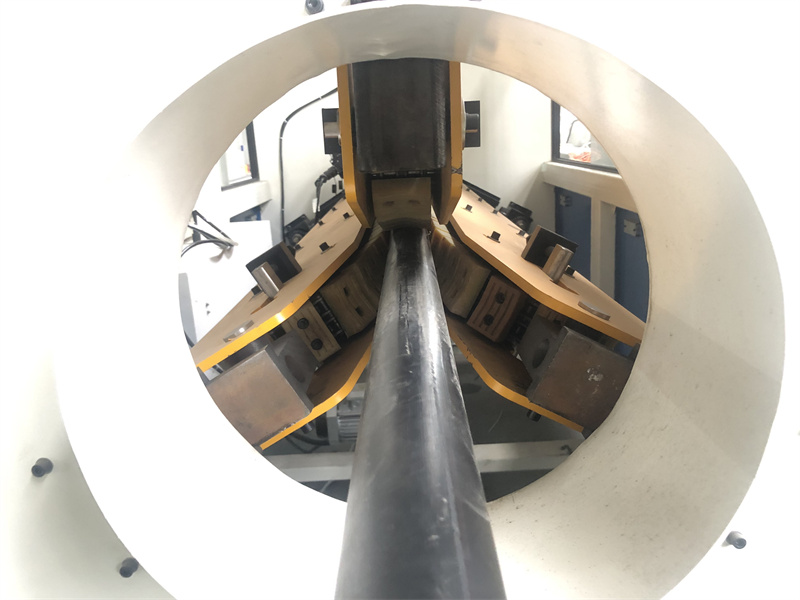

Mould

The mould has spacious flow channel design to guarantee high extrusion capacity and good melting effect. It is made and inspected by the experienced manufacturer. The optimized temperature control and flow channel design ensures precise melt temperature control.

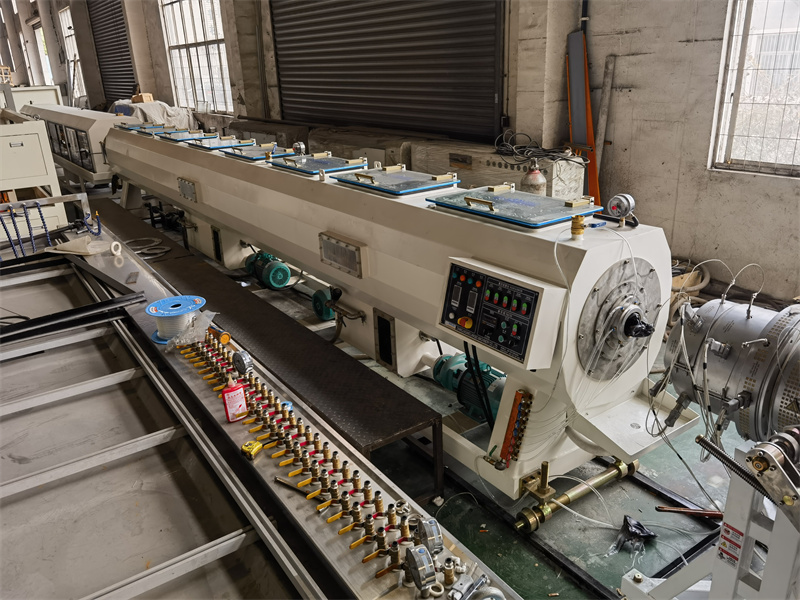

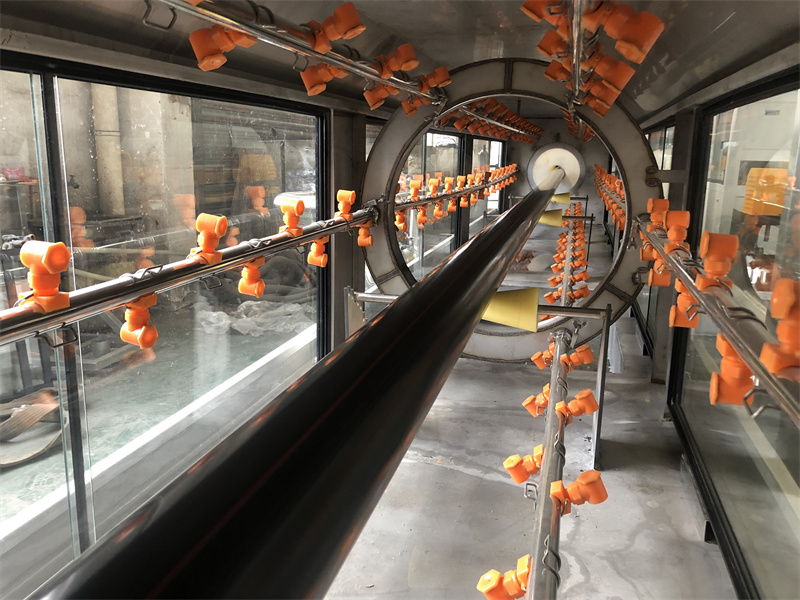

Vacuum and cooling tank

This line adopts 6m vacuum and 8m cooling tank equipped with 2 vacuum pumps and 4 water pumps. The cooling tanks have enough nozzles continuously providing cold water to cool the pipe. After enough length of the pipe, the product is smooth and sturdy.

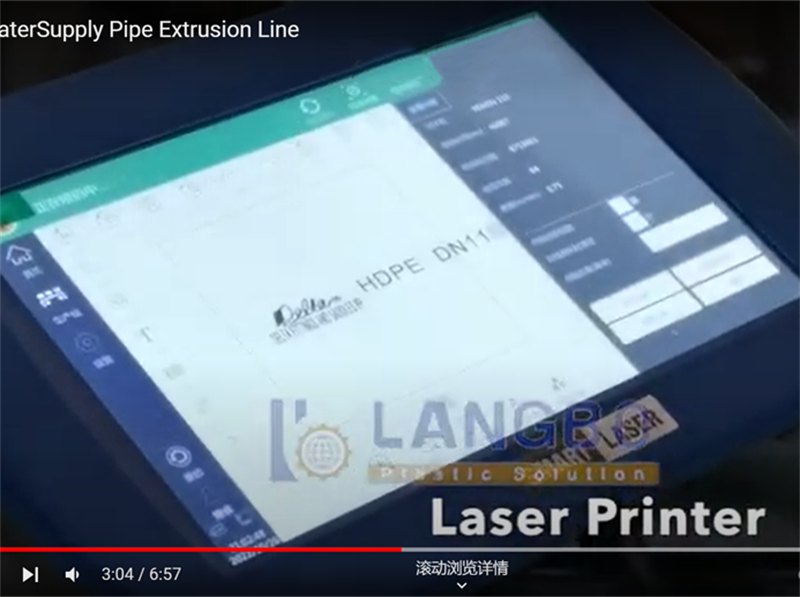

Laser Printer

The laser printer has smart system and encoder. It will be automatically printing at the exact length. We just program it and it will print the logo, type, diameter and any other needed.

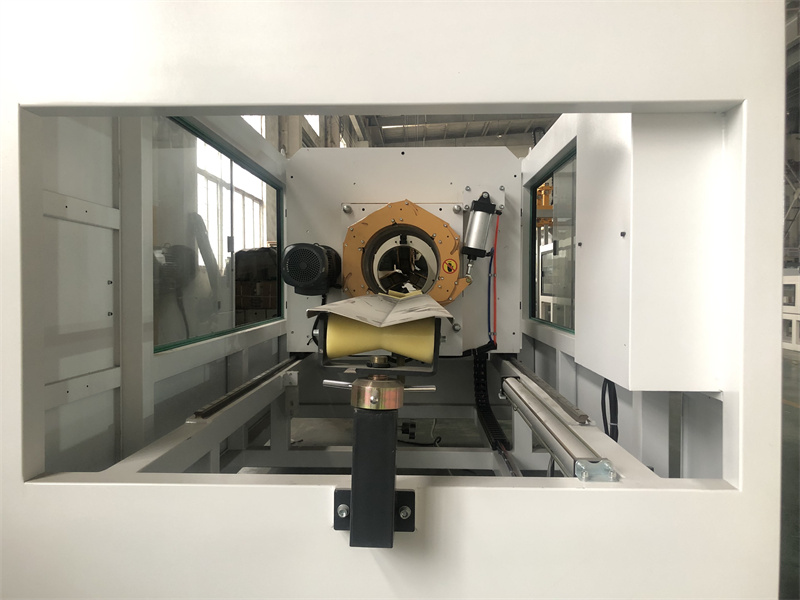

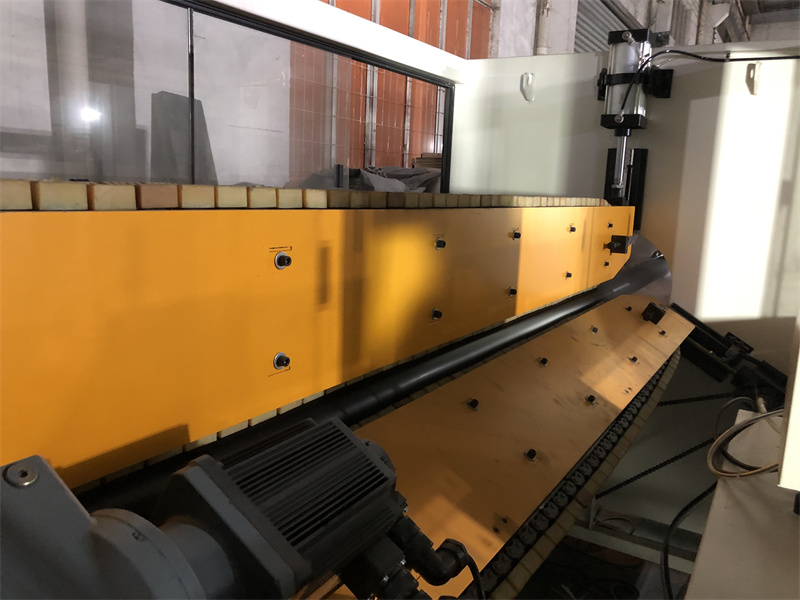

Haul-off Unit

The three caterpillar haul-off machine ensures the HDPE pipe running stably and steady. Our unique haul-off design assures proper pulling without slippage. And the control speed is program and automatically control as the extruding speed.

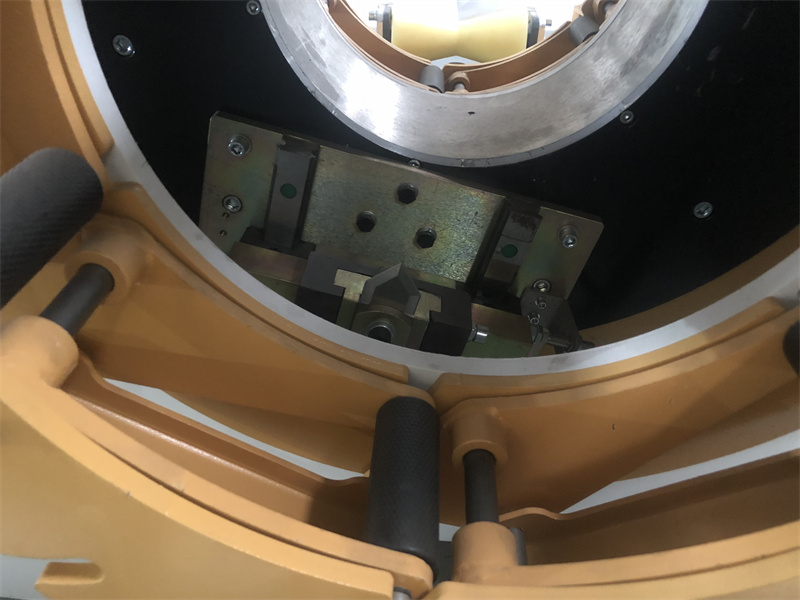

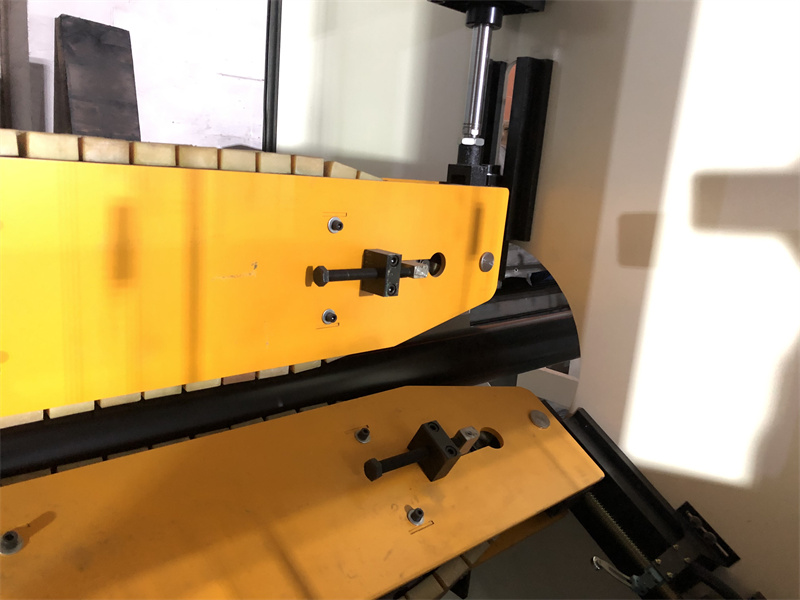

Cutting Unit

We offers no-dust cutting method. The sharp cut ensure the smooth of the pipe and the cutting action happens automatically.